Industrial Automation / Process Control

Smoother, safer, more efficient industrial processes thanks to industrial automation.

Automating your processes is a key step in gaining flexibility and limiting repetitive tasks in your operations.

By automating tasks, you can not only reduce human error, but also increase your production yields and optimize your energy and raw materials consumption.

This transformation enables your teams to concentrate on high value-added missions, optimizing your human resources.

With real-time control, you benefit from increased reactivity and improved efficiency, guaranteeing optimum performance of your industrial operations.

Technord supports your digital transformation as anindustry 4.0/5.0 expert.

Our industrial automation certifications.

With Technord, meet all your industrial challenges

in process control

& digitalization.

With 70 engineers and technicians, our Process Control and Industrial Automation department can support you throughout your projects, from design to maintenance of your automated systems, providing you with their expertise.

Our objective? To optimize every aspect of your production line and processes, so that you can get the most out of them (productivity, energy consumption, raw material consumption, profitability, safety, compliance, real-time supervision, historical data processing, historical records, etc.), while respecting people.

How can we achieve this?

With our project management approach based on the V-cycle and Agile mode, our expertise in multiple projects for varied and demanding sectors, also through mastery of the standards applicable to these sectors.

Contact us >

Technord designs, integrates and maintains all your automation projects.

blank

Industrial automation

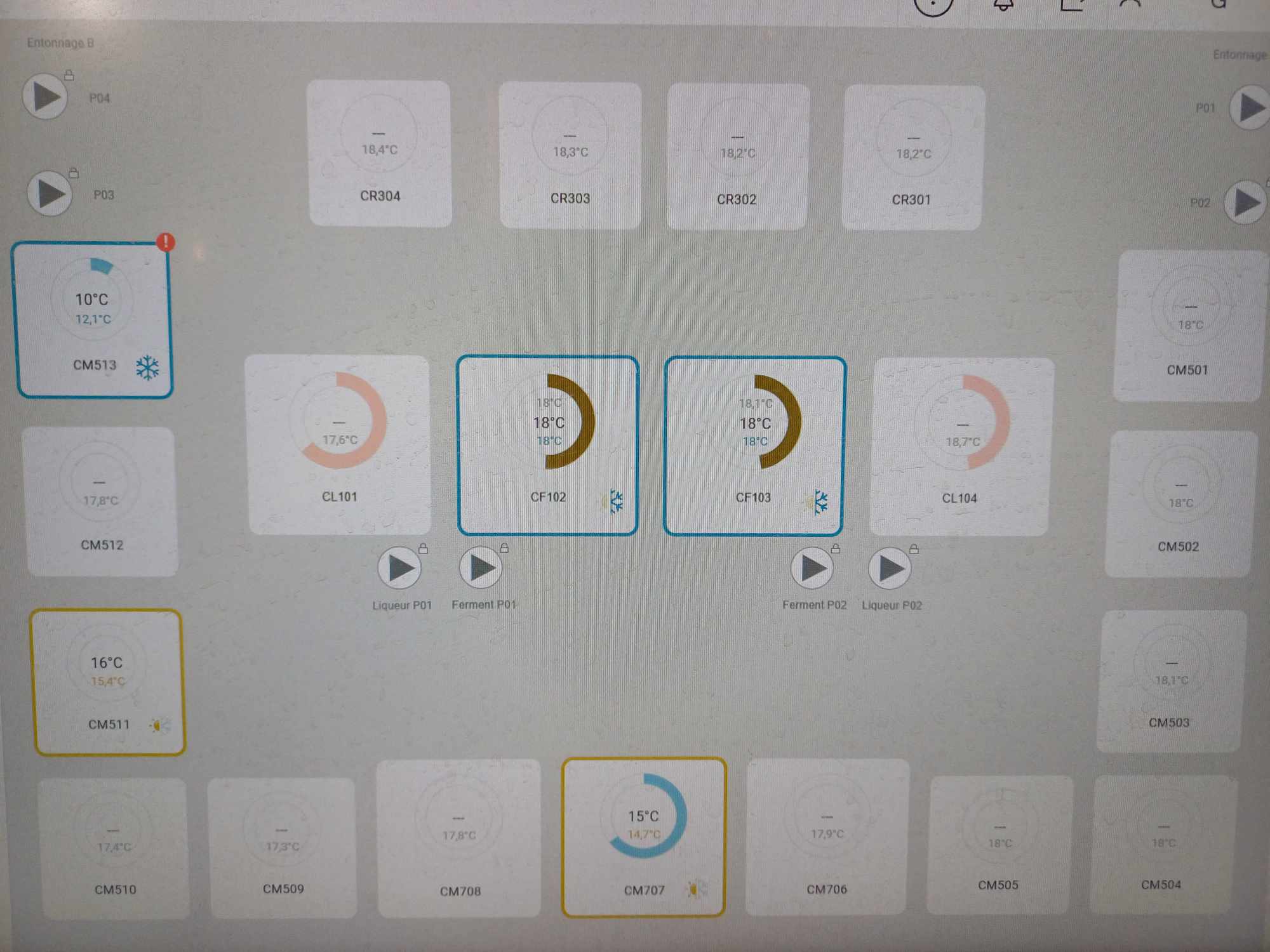

Ensure the design and integration of control-command systems that allow for the supervision and management of industrial processes while minimizing human intervention.

Technord handles your process automation projects from A to Z (study, development and design, drafting of project specifications, testing, commissioning, training, maintenance…).

Industrial communication

Connect each department of your industry within a single networked system that encompasses your entire value chain, from your management team to your field agents, for seamless communication and increased productivity.

To achieve this, Technord uses and combines a number of technologies:

- Wired or optical networks for Ethernet (Profinet, Ethernet IO, Ethernet IP, Modbus TCP/IP) or multidrop (Profibus, ASI, Modbus RTU) technologies

- Wii-Fi or telecommunications networks (4G, 5G, IoT) to ensure interfaces with mobile equipment or off-site customers

- Remote maintenance and remote control of equipment to secure your external connections

- IO Link is a manufacturer-independent point-to-point interface for connecting sensors and actuators, in accordance with IEC 61131-9.

Industrial safety

Technord integrates solutions and tools to give you a real-time overview of the compliance and safety of your machinery.

Technord enables you to ensure better machine availability by limiting downtime, and to reduce risks to your employees by complying with applicable directives.

- Checking the condition of your machines and their compliance with current legislation and standards

- Remediation and compliance plan for your machines

- Real-time risk analysis

- Sizing and implementation of safety components

- Selecting and configuring security networks

- Programming programmable safety controllers

Batch Control

Integrate high-performance batch systems to ensure batch processing of your production with perfect traceability, optimum compliance with quality standards and improved efficiency of your production operations.

- Implementation of flexible, reliable management software via our partner suppliers(Wonderware, Siemens, Rockwell ; all compliant with ISA Standard 01).

Motion control / Servo system

Control every movement and operation of your machines in terms of motion, speed and precision (high-speed packaging lines, filling, Cartesian robots, product cutting, tool positioning, advanced safety features…).

- Design, integration and programming of all your servo-drive systems via leading motion control suppliers (Rockwell Automation, Siemens and SEW).

Distributed Control System (DCS)

Decentralized control of your processes and production units to boost efficiency and reliability, especially in large-scale industrial environments.

When it comes to industrial automation, Technord can handle your DCS (Siemens) project from A to Z:

- Definition of the architecture to be implemented.

- Design standard objects and libraries.

- Application development

- Simulation of manufacturing processes for FAT testing.

- Commissioning and support for your teams

- Training and after-sales service

Cybersecurity

Technord offers you a progressive, iterative approach to cybersecurity, working with recognized partners to meet current standards (NIS 2, ISO 27001, IEC 69453 series, CCB(Centre pour la Sécurité Belgique), Cyberfundamentals framework…).

- Assessment and strategy / Current situation

- Audit of your IT and OT networks

- Risk assessment

- Definition of priorities in terms of realization

- Implementation

- Hardware definition

- Installation, commissioning and support

- Training

- Continuous improvement support

- Monitor, defend and recover your industrial data, to deal effectively with any level of cyber-attack risk.

Predictive and automatic control

Using artificial intelligence, Technord helps you maximize yields and production quality in real time, while minimizing your costs (energy, raw materials, etc.).

impact assessment

We offer an impact assessment tool.

Discover our TAMI tool

Feedback from our experts.

Testimonials

Marcel Willems, Automation Manager

“Our Automation and Process Control department plays a key role in the continuous improvement of our customers’ operations.

Our technical expertise and innovative approach enable us to transform our customers’ industrial processes, making them not only more efficient, but also more reliable.

Our projects are a real success, thanks to a deep understanding of needs and an ability to propose tailored solutions, whether for automating complex tasks, optimizing production lines or implementing advanced control systems. “

Feedback from our experts.

testimonials

Technord projects & references

in industrial automation

& process control.

Decarbonization project

Automation of a new crusher capturing the CO2 emitted during lime production

See more

Automation and traceability

Analysis, solutions, support, training, follow-up, Retex and improvements

See more

Find out more about our expertise in industrial automation ?

Our team will advise you and help you choose the best solutions.

Together, we can boost your industrial performance tenfold!

Contact us >