The challenge

Cement production is quite complex and difficult due to the variability of raw materials, the different chemical reactions involved, and the inertia of devices such as a precalciner, a rotary kiln and a cooling system.

The basic component of cement is clinker. Clinker is produced from limestone and other mineral components such as silicates, aluminates and so on. One of the first stages is the transformation of limestone into lime, known as decarbonation. It begins during the preheating process and ends in the kiln. As the kiln has slow dynamics, the stone must be well prepared beforehand to avoid numerous corrections. Preheating must therefore be well managed and achieve a specific decarbonation objective. The latter is assessed very few times a day, and this is of little help to the operator in charge of production. What’s more, the preheating system burns alternative fuels that are less expensive than those dedicated to the furnace, so it’s preferable to make greater use of the precalciner and save the fuel used for the furnace.

The solution

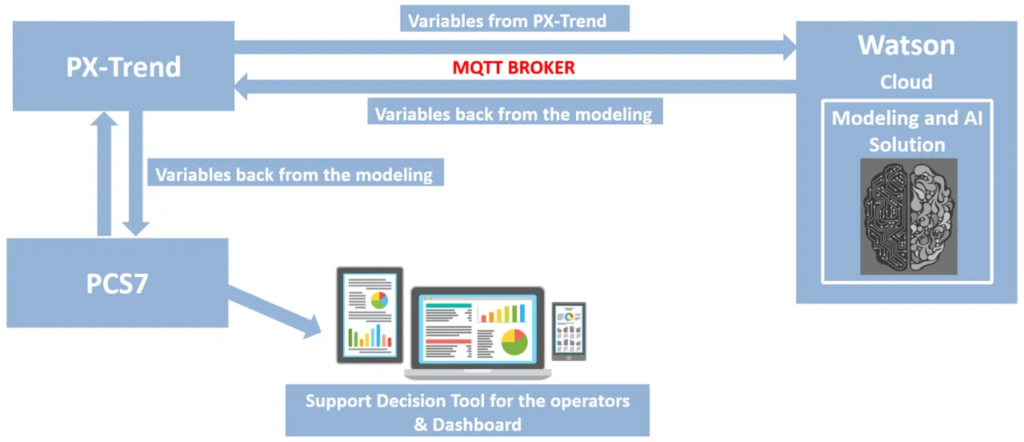

By developing a mix of physical balances and statistical modeling, and using high-frequency on-line measurements, the decarbonation stage can be dynamically estimated, and this software sensor suggests to the operator the amount of energy needed to achieve optimum decarbonation. This means that this quality KPI is online, helping the operator to make the right decisions.

The potential gain

This software sensor suggests to the operator the right amount of energy to ideally decarbonate the limestone before it enters the kiln.

This finer decarbonation eliminates the need for delicate correction manipulations in the kiln, saving time, kiln energy and stable clinker quality. Energy savings and increased production time significantly improve performance KPIs (margin in euros/tonne produced).

This type of innovation is also important for maintaining business in Europe by ensuring competitive production. As a reminder, this is one of the foundations of Industry 4.0.

Find out more about this Data Science project with Technord

Customer activity

- Mining and quarrying

- Cement/lime production

- Limestone decarbonation

Solution brand

- Siemens

- PCS7

- PX-Trend

- IBM

- Watson

- Maximo

- Python

Type of work

Services

- Decision-making tool

- Software sensors