Objective

Storing production data has been a must for our customers for years. But what are we really doing with this data? A number of supervision platforms can store a substantial amount of data, but this information is not always used optimally.

With the arrival of Industry 4.0, the industrial world’s desire is to be able to correlate information from the field with information coming directly from the ERP. So it’s important to pay due attention to useful data.

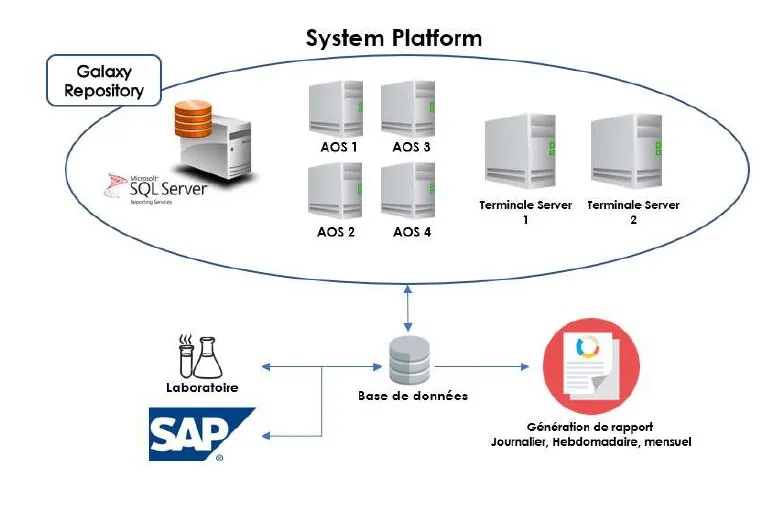

With an architecture made up of over 13,000 historical variables, Technord’s objective was to highlight useful data in the form of a report, SAP link, etc.

Our contribution

To this end, we developed a series of daily, weekly and monthly reports to highlight the information needed to run the plant smoothly. In addition, an SAP link has been developed via an exchange database for retrieving laboratory data.

The benefits

Production line deviations are better identified, as is line management. In addition, the connection with the SAP system has enabled a direct link with production data. This has enabled product quality to be better targeted, thanks to regular sampling and correlation of results with field data.

Further information on this project

Customer activity

- Mining and quarrying

Technical details

- System Platform Wonderware

- Reporting Service